JB Blind Flanges

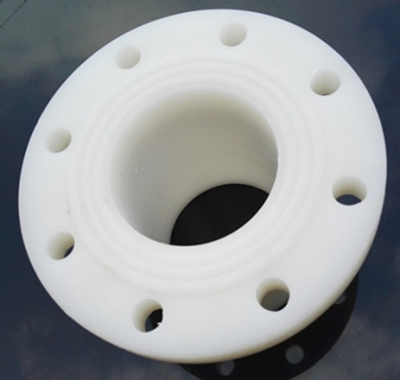

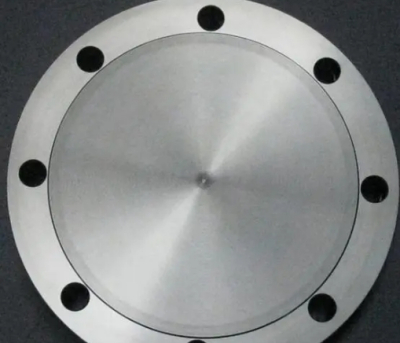

The formal name of blind disk is Flange cover, and some are also called blind flange or pipe plug. It is a flange without a hole in the middle and is used to seal the pipe opening. The function is the same as that of the head and cap, except that the blind seal is a removable sealing device, and the seal of the head is not ready to be opened again. There are many types of sealing surfaces, including plane, convex, concave and convex surface, tenon and groove surface and ring connection surface. The materials are carbon steel, stainless steel, alloy steel, copper, aluminum, PVC and PPR

The formal title of blind disk is Flange cover, and some are additionally referred to as blind flange or pipe plug. It is a flange barring a hole in the core and is used to seal the pipe opening. The function is the equal as that of the head and cap, barring that the blind seal is a removable sealing device, and the seal of the head is now now not outfitted to be opened again. There are many types of sealing surfaces, which consists of plane, convex, concave and convex surface, tenon and groove flooring and ring connection surface. The components are carbon steel, stainless steel, alloy steel, copper, aluminum, PVC and PPR.

From the appear of the blind plate, it is usually divided into plate type flat blind plate, mother or father eight blind plate, plug board, and gasket ring (plug board and gasket ring are blind to each other). The blind plate performs the role of isolation and cutting, and the function of the head, pipe cap and welding plug is the same. Due to its notable sealing performance, it is generally used as a reliable ability of isolation for constructions that require complete isolation. A flat plate blind is a robust circle with a cope with that is used in buildings that are generally isolated. The figure-8 blind plate is original like a figure-8, one stop is a blind plate, and the unique provide up is a throttle ring, on the other hand the diameter is the equal as the diameter of the pipe, and it does no longer play a throttling role. The figure-8 blind plate is easy to use, when it wishes to be isolated, the blind plate end is used, and when normal operation is required, the throttle ring cease is used, and it can moreover be used to fill the set up gap of the blind plate on the pipeline. Another attribute is that it is simply marked and handy to find out the set up status.

Production process

Generally, there are four types: forging, casting and forging, medium plate cutting, and casting. Among them, the charge of forging merchandise is the highest, accompanied by using way of medium plates, and casting and forging is the lowest. Casting is the most most desirable process. The high-quality is correct for forging and core plates, and the casting and forging are barely worse.

Where the blind plate is applied

1. In the special start-up preparation stage, when the strength take a seem at or tightness take a appear at of the pipeline cannot be carried out at the equal time as the associated equipment (such as turbines, compressors, gasifiers, reactors, etc.), a blind plate have to be set at the connection between the equipment and the pipeline.

2. When the device is stopped, if the pipeline is then again in operation, a blind plate is set at the shut-off valve.

3. When the machine is multi-series, the predominant pipeline from outside the boundary location is divided into lots of pipes to enter each series, and a plate is set at the shut-off valve of each sub-pipeline.

4. When the gadgets desire to be generally maintained, inspected or switched with each other, and the equipment involved needs to be without a doubt isolated, a blind plate is set at the shut-off valve.

5. When the process pipeline of the pressurized pipeline and the displacement gasoline pipeline (such as nitrogen pipeline and compressed air pipeline) is associated to the equipment, a plate is set at the shut-off valve.

6. If the method medium needs to be focused in a unified collection system, a blind plate have to be set up in the returned of the shut-off valve.

7. The exhaust pipe, liquid discharge pipe and sampling pipe of equipment and pipeline want to be furnished with blind plate or plug in the returned of the valve. Except for resources that are non-toxic, non-hazardous to health and non-explosive hazards.

8. When the machine is constructed in stages, the interconnected pipelines are set up at the shut-off valve to facilitate the subsequent constructing of the project.

9. When the machine is in normal production, some auxiliary pipelines that prefer to be absolutely limit off ought to generally be set up with blind plates.