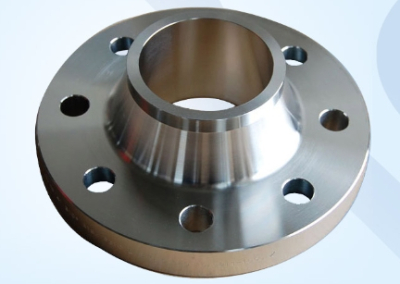

The butt welding flange is now not effortless to deform, seals well, is broadly used, has the corresponding inflexible and elastic requirements and practical butt welding thinning transition, the welding joint is a long way from the joint surface, and the joint floor is blanketed from welding temperature deformation, it adopts a greater complicated cough flare structure, which is appropriate for pipelines with giant fluctuations in strain or temperature or pipelines with excessive temperature, excessive strain and low temperature, and is usually used for the connection of pipelines and valves with PN increased than 2.5MPa, and is additionally used for transporting expensive, flammable and explosive medium pipelines.

Forging, casting, and mid-plate turning

Flat welded flanges

Connection form: Single-sided welding, double-sided nut connection.

Product points Beautiful appearance, clean surface, acid and alkali resistance, anti-corrosion, sturdy texture performance.

Production process: Oxygen furnace cutting, necessary forging or completed product forging and reducing forming.

Processing method: high-precision CNC lathe turning, CNC radial drilling and drilling.

Product parameters

(2) Bolt gap middle circle diameter: 50mm----2130mm

(3) Bolt gap diameter: 11mm-30mm

(6) Flange thickness: 12mm-58mm

(7) TUBE OUTER DIAMETER: A(17.2-2032MM) B(14-2020MM)

(8) Flange internal diameter: A(18-2036MM) B(15-2024MM)

(9) Flange theoretical weight: 0.36kg--234.6kg (DN1800)