Characteristics and uses of aluminum alloy flanges

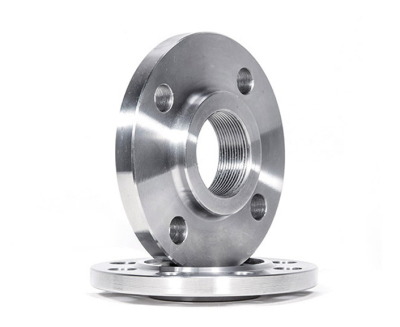

Aluminum alloy flange is a part of the connection between the pipe and the pipe, the main role is used for the connection between the pipe, there are also some flange used in the import and export of the equipment for the connection between the two equipment. Aluminum alloy flange connection or flange joint refers to the flange plate and bolt three connected to each other, as a group of assembly, sealing structure can be disassembled and connected.

Aluminum alloy flange is a silver-white light metal, with good ductility, in the humid air can form a layer of anti-purple gold decay oxide film, rice flour and aluminum foil in the air heating can be violently burned, and can also emit dazzling white or. The characteristics of the flange are easy to dissolve in diluted sulfuric acid, nitric acid and hydrochloric acid solutions, but it is difficult to dissolve in water. The content of aluminum in the aluminum alloy flange in the crust is second only to oxygen and silicon in the third place, is a rich content of a metal element.

In the three important industrial developments of aviation and construction vehicles, this material is required to have the unique properties of aluminum and aluminum alloys, which is more conducive to the production and application of new metal aluminum. Therefore, the application of aluminum alloy flanges is now very extensive. The aluminum alloy flange as a whole uses a splicing method, that is, when you connect the same air duct size, paste a flame retardant seal in the heat insulation groove of the pipe, and the pasted seal should be very tight and smooth, without any defects.

After the flame retardant seal is pasted, the pieces of the seal plate are aligned, and then the tear is temporarily fixed with a wrench, and then the cutting is installed in the outer buckle of the flange. Aluminum alloy flanges are now manufactured in the aerospace field for fastening parts. Now aluminum alloy flanges have corrosion resistance, which is not the condition of some other hands, because the surface of the aluminum alloy has a very strong film, this film covers the surface of the aluminum alloy, so that the aluminum alloy and oxygen are isolated.

With the continuous extension of time, the film will continue to thicken, if this layer of film is damaged, then it will re-grow to protect us, which also makes the aluminum alloy flange has very good corrosion resistance, of course, in the later stage, it is still necessary to carry out surface treatment cooperation to enable the development of aluminum alloy, more corrosion resistance. Many people think that you are a kind of material that will not be oxidized, in fact, this idea is wrong, it is just that the conditions and degrees of their oxidation are not the same, if the surface protective film of the aluminum alloy flange is damaged, then its body will be oxidized.