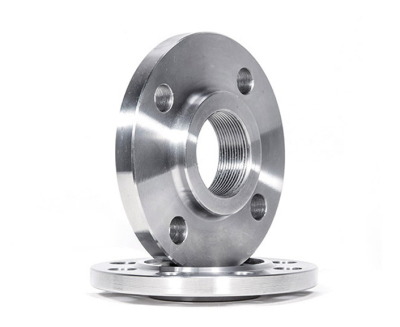

High Pressure Flanges

High-pressure flange: A flange used for the connection of pipes or gear with a stress greater than 10MPa. It in most cases consists of regular high-pressure flanges and high-pressure self-tightening flanges.

Product Overview

Traditional high-pressure flange: It is a section that makes use of the plastic deformation of the sealing gasket (oval gasket, octagonal gasket, lens gasket, etc.) to gain the sealing effect, is linked to the pipe end, and the pipe is linked with every other.

Product Introduction

Traditionally, it consists of a pair of flanges, a spacer, and a quantity of bolts and nuts. The gasket is set up on the sealing floor of the two flanges

After tightening the nut, the precise strain on the floor of the gasket reaches a sure value, so that the connection is tight and does now not leak. This structure can be used in flammable, explosive, poisonous media and excessive stress activities however the sealing reliability is poor.

Features:

1. The sealing precept belongs to plastic deformation

2. Bolt connection

3. The bolt need to endure tensile force, temperature distinction stress, and many exterior stresses such as bending second and torque

4. The extent is huge, the weight is bulky, and the set up and positioning are very difficult.

5. The sealing overall performance is unstable, particularly in the harsh case (high temperature, excessive pressure, and incredibly poisonous medium), which is convenient to leak, inflicting serious consequences.

Application characteristics

The high-pressure flange is in the main used in the set up of pipelines, and the high-pressure flange connection is an essential connection mode for pipeline construction, which primarily connects the connection between pipes and performs an essential function and value. The high-pressure flange connection is to restoration two pipes, pipe fittings or tools on a flange plate first, and between the two flanges, add flange pads, and fasten them collectively with bolts to entire the connection. Some pipe fittings and tools already have their personal flanges, which are additionally flange connections. [1] High Pressure Flange Product Performance:

1. Wear resistance: the content material of Al2O3 in the ceramic layer lined with ceramic composite metal pipe is higher than 95%, and the microhardness is HV1000-1500, so it has extraordinarily excessive put on resistance, and its put on resistance is greater than ten instances greater than that of quenched medium carbon steel, which is higher than tungsten drilling cemented carbide.

2. Corrosion-resistant ceramics are impartial materials, with secure chemical properties, amazing corrosion resistance and acid resistance, and can face up to a number inorganic acids, natural acids, natural solvents, etc., and its corrosion resistance is extra than ten instances that of stainless steel.

Material

Carbon Steel: ASTM A105, 20#, Q235, 16Mn, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70

Stainess Steel: ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

Alloy Steel: ASTM A182 F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo,

Imported material: [1] (nickel steel), WC5 (1.25% chromium 0.5% molybdenum steel), WC9 (2.25% chromium), C5 (5% chromium p.c molybdenum

High-pressure flanges typically refer to flanges used to join pipes and equipment, and their fundamental aspects and blessings include:

Withstand excessive pressure: The high-pressure flange graph is in a position to stand up to excessive pressure, making sure that the piping gadget operates reliably beneath excessive stress conditions.

Strong corrosion resistance: high-pressure flanges are generally made of high-strength alloy metal or stainless steel, which have desirable corrosion resistance and are appropriate for the transportation of corrosive media.

Good sealing: The connection shape diagram of the high-pressure flange makes it have properly sealing performance, which can successfully stop the leakage of the medium and make sure the secure operation of the pipeline system.

Easy set up and maintenance: The high-pressure flange is bolted, which is handy and rapid to set up and disassemble, and effortless to hold and replace.

Wide vary of application: high-pressure flanges are appropriate for high-pressure pipeline structures in more than a few industrial fields, such as petrochemical, electric powered power, papermaking, metallurgy and different industries.

In general, high-pressure flanges have an vital position and software in high-pressure pipeline structures due to their benefits of excessive strength, corrosion resistance, accurate sealing and handy installation.