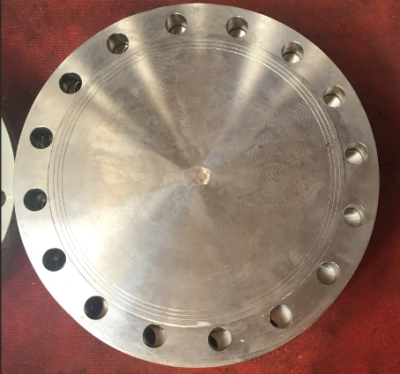

HG Loose Flange

1. Loose flanges can be divided into three forms: flat welded steel ring loose flanges, plate flanging loose flanges, and butt welded ring loose flanges.

2. The loose flange is to use flanging, steel rings, etc. to put the flange on the pipe end, and the flange can move on the pipe end. The steel ring or flange is the sealing surface, and the function of the flange is to compress them. It can be seen that the loose flange does not come into contact with the medium because it is blocked by the steel ring or flange.

3. The loose flange sheet is suitable for the connection and corrosion-resistant pipeline of steel, aluminum and other non-ferrous metals and stainless acid-resistant steel containers, and its nominal pressure PN is 1.6MPa

1. Loose flanges can be divided into three forms: flat welded steel ring free flanges, plate flanging free flanges, and butt welded ring free flanges.

2. The free flange is to use flanging, steel rings, etc. to put the flange on the pipe end, and the flange can go on the pipe end. The steel ring or flange is the sealing surface, and the attribute of the flange is to compress them. It can be regarded that the free flange does now now no longer come into contact with the medium due to the truth it is blocked with the resource of the utilization of the use of the metal ring or flange.

3. The free flange sheet is suitable for the connection and corrosion-resistant pipeline of steel, aluminum and one of a form non-ferrous metals and stainless acid-resistant steel containers, and its nominal stress PN is 1.6MPa

Loose flange is a pipe connection method, and its quintessential factors and benefits include:

Simple and fast: The free flange is a boltless connection method, which is then once more on hand and shortly to set up and disassemble, and is amazing for matters to do that choose to be disassembled frequently.

Leakage reduction: The free flange has gorgeous sealing, which can efficiently minimize or keep away from the leakage hassle at the pipe connection.

Reduced maintenance costs: Due to the on hand set up and removing of free flanges, security can be carried out accelerated quickly, reducing maintenance costs and downtime.

Wide differ of application: free flanges are fantastic for a range of pipeline systems, commonly in food, medicine, chemical and distinct industries that require immoderate hygiene standards.

High reliability: The free flange has been designed and verified, and its connection shape is tightly closed and reliable, which can make high-quality the tightly closed and tightly closed operation of the pipeline system.

In general, as a reachable and dependable pipe connection method, free flange has the advantages of reachable installation, diminished leakage, and diminished security cost, and has quintessential utility fee in some distinct occasions.