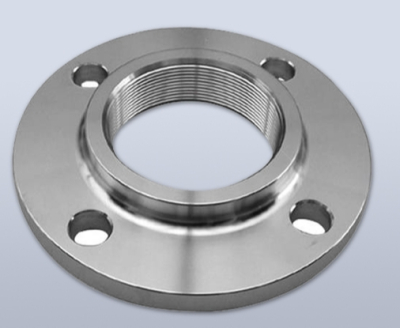

Socket Welding Flanges

Socket welded flange is a commonly used pipe connection method, and its features and advantages include:

Good fastening: The socket welding flange connects the pipe by welding, the weld is firm, the connection is tight, and it has good sealing performance.

Socket welded flange is a commonly used pipe connection method, and its features and advantages include:

Good fastening: The socket welding flange connects the pipe by welding, the weld is firm, the connection is tight, and it has good sealing performance.

Strong compressive capacity: The welded connection method makes the socket welded flange can withstand large pressure, which is suitable for high-pressure pipeline system.

Corrosion resistance: Reduced risk of corrosion and improved corrosion resistance of piping systems due to the elimination of contact parts such as threads due to welded connections.

Good aesthetics: there are no additional bolts and threads after the socket welding flange is connected, and the appearance is neat and beautiful.

Space-saving: Compared to threaded flanges and socket flanges, socket welded flanges do not require additional flange area and bolt fittings, which can save space at pipe joints.

Wide range of application: socket welded flange is suitable for a variety of piping systems, and can connect pipes of different materials and different pressure levels.

Although socket weld flanges have many advantages, they also need to pay attention to welding technology and quality in the application to ensure that the weld quality meets the standard requirements and avoid welding defects. In addition, material selection is also the key, and the appropriate welding material should be selected according to the specific engineering requirements to ensure the reliability and stability of the connection.